Our Capabilities

American Industrial Group can take a project from an idea to finished facility.

- Project Development

- Detailed Design

- Project Management

- Automation

- Fabrication

- Installation

- Rotary Dryer Service

- Support Services

- Palcut Packaging

PROJECT DEVELOPMENT

American Industrial Group assists customers with their capital projects to build new plants, expand existing facilities, upgrade processes with new technology, renovate outdated facilities, and more.

Our team’s services vary and often include:

- Project definition / scope

- Project configuration and charters

- Site selection

- Site preparation

- Permit activities

- Process description

- Preliminary design

- Project budget

- Project schedule

DETAILED DESIGN

AIG supports industrial customers with a full scope of engineering services. Our technical experts work closely with operations staff to understand the business, processes, challenges and opportunities and deliver smart, cost-effective designs.

- Automation

- Process development

- Process design

- Process flow diagrams (PFDs)

- Process and instrumentation diagrams (P&IDs)

- Raw material receiving and unloading

- Start-to-finish material handling

- Packaging systems

- Warehousing

- Load-out systems

- Dust collection

- Process controls

- Equipment/system design and specification

- Equipment bid review and tabulation

- System evaluation

- System troubleshooting

- Facility/building design

- Structural design

- Building systems — power distribution, HVAC, utilities

PROJECT MANAGEMENT

AIG manages all project phases, from kick-off through construction, from programming to system start-up. We provide a single point of contact across design disciplines and contractors. Customers trust us to run projects efficiently and transparently, communicating progress, addressing challenges directly and resolving problems.

- Schedules

- Budget

- Subcontractors

- Change order management

- Equipment installation

- Equipment fabrication

- Field reports

- Construction management

- Owner’s representative

- Design/build

- Job-site safety

- Project documentation

AUTOMATION

Automation allows systems, even buildings, to work smarter and more efficiently. Automation is more than smart technology. It relies on smart expertise. American Industrial Group’s industrial automation experts identify tools, including robots, PLCs, and instrumentation, that can effectively communicate. The result? Manufacturing and material handling systems designed to:

- Reduce costs

- Minimize variation

- Maximize flexibility

- Reduce waste

- Improve safety

- Improve throughput

- Minimize downtime

AIG team members have designed and implemented automation in a wide range of environments:

- Insulation manufacturing

- Agricultural equipment manufacturing

- Law enforcement

- Agricultural research

FABRICATION

Mechanically integrating equipment into a working system requires supports and connections.

Quite often those parts are not available right off the shelf. Instead, AIG designs the equipment supports, personnel access points, equipment pads and the mix of parts and pieces that connect one piece of equipment to another. Our AutoCAD designers generate the shop drawings and ultimately sign off on high-quality parts from the skilled fabrication shops we use.

Our resources also provide repair services for custom fabricated parts.

In addition to fabricating parts and pieces to physically integrate equipment into a functional system, AIG will design and oversee fabrication of custom pieces such as tanks, baghouses and building framing.

We have provided fabrication services a range of systems, including:

- Insulation packaging systems

- Chicken fat CIP system

- Salt processing plants

INSTALLATION

From concept to start-up, AIG transforms design into reality. We do it safely, within budget, on schedule, and we do it right.

Jobsite safety is priority. All AIG project managers hold OSHA 30 certification. Safety coordinators monitor and report safety issues and conduct training for our crews.

The AIG team meets customer needs at any point in the installation process, from pouring foundations and erecting steel to receiving equipment and putting it in place. We provide skilled resources with proven track records for performance and jobsite safety. AIG brings all trades needed: millwrights for mechanical installation, electricians for electrical services, programmers for PLC and automation – whatever the job requires.

AIG project managers work closely with plant managers to ensure manufacturing operations effectively continue during construction and installation. We stay on the job through commissioning so our customers know the system is working as designed.

In addition to industrial applications, AIG team members have been involved in the installation of a new 3,800-pipe pipe organ; equipment and facilities in a county jail; aquatic center and water park; and build-out of a preschool and day care facility.

ROTARY DRYER SERVICE

AIG provides proprietary maintenance and repair technology

developed over decades in the industry.

The AIG team delivers the knowledge and experience to meet your dryer service needs. Our rotary dryer technicians inspect, maintain, repair and replace all elements of rotary dryer equipment.

- Aligning and resurfacing

- Drum crack repair

- Drum replacement

- Drum structural repair

- Inspections

- Parts and components

- Drive, bearings and trunnions

- Emissions and combustion

- Product and gas conveyance

SUPPORT SERVICES

AIG can support our customers’ success beyond delivery of the last drawing, checking the final item on a punch list, or loading the first package into a rail car. The AIG team provides front-end analysis, troubleshooting, training and ongoing support.

- Process support activities

- System troubleshooting

- System evaluation

- Drawings and documents

- As-built drawings

- 3D models

- General layouts

- Installation details

- Equipment/motor lists

- Documentation

- Manuals

- Users guides

- Operating manuals

- Training manuals and other materials

- Standard operating procedures

- Job aids

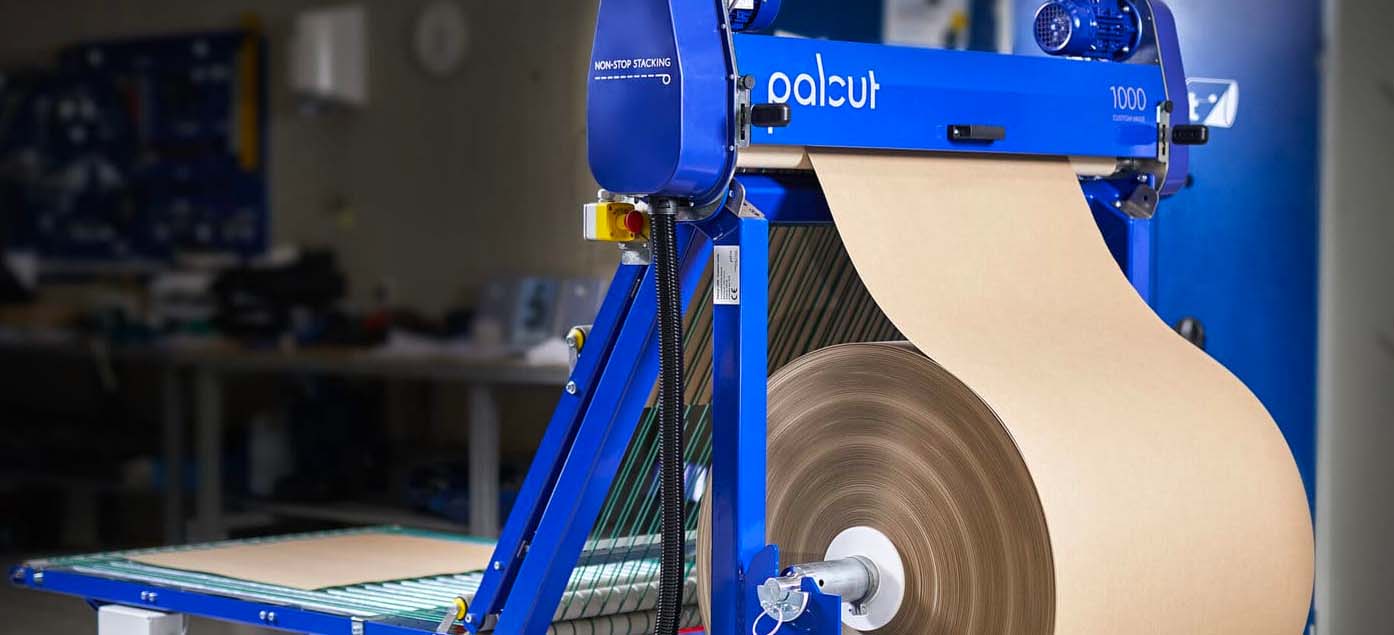

PALCUT’S NON-STOP STACKING SOLUTION

For high efficiency, high productivity palletizing solutions, AIG is the source for Palcut sales, installation and service in the US market. Based in Denmark, Palcut manufactures slip sheet papers and a fully programmable roll dispenser. AIG’s relationship with Palcut leverages our years of experience in packaging processes.

Palcut’s patented non-slip paper is one key to the system.

- Palcut’s Antim® paper has a slip angle exceeding 50° to help stabilize pallets during transport.

- The revolutionary, high-friction coating ensures optimal grip and binds the layers together.

- Goods are securely transported internally, over the road and all the way to the customer.

Learn more about AIG and the Palcut palletizing solution…